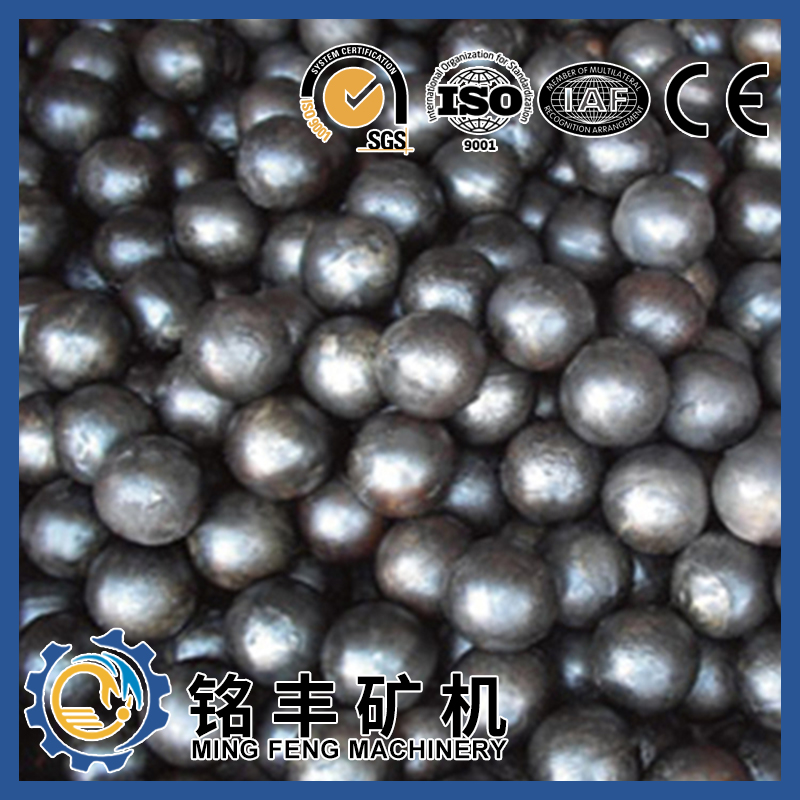

Kubbada wax lagu shiidi karo ee birta ah

Dulmar:

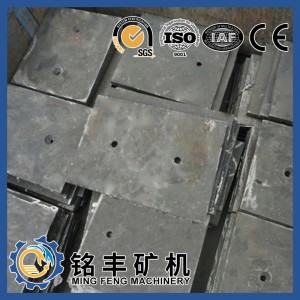

| Nooca | Looxa xadhkaha burburiya, saxan dahaarka ah | ||

| Asal ahaan | Shiinaha | Koodhka HS | 84749000 |

| Xaalad | Cusub | Shidida macdanta | Quartz, dahab dahab ah, clinker sibidhka, iwm. |

| Nooca Mashiinka | Ball Mill Liner | Shahaado | ISO 9001:2008 |

| Qalabka ugu muhiimsan | Mn13Cr2 , Mn18Cr2, Mn22Cr2, Cr22, Cr26 | ||

| Nooca Habaynta | Qaadista | Daaweynta Dusha sare | Rinjiyeynta/buufinta-Rinjiga |

| Kormeerka jilitaanka | Qalabka Spectrum-akhrinta tooska ah, Falanqaynta Metallographic, Kormeerka Ultrasonic, Baadhitaanka Qaybaha Magnetka, Kormeerka Guryaha Makaanikada | ||

| Xidhmada Gaadiidka | Ku baakadsan Pallet/Kiiska | Dammaanad qaad | La mid ah Asalka |

| Tayada | Heerka Sare | Khibrad | In ka badan 30 sano |

Sharaxaada:

Deegaanka kubad-shiidka aasaasiga ah waxaa sida ugu wanaagsan loogu sifayn karaa iyadoo la siinayo tixgelin isku mid ah saameynta iyo xaaladaha xoqitaanka labadaba.Cabbirrada kubbadda oo aad u weyn ee la shaqaaleysiiyay [3″ – 4″ (75 – 100 mm)] waxay gacan weyn ka geystaan xirashada guud ahaan.Tirada saamaynta shiidlada kubbadda aasaasiga ah aad ayay u badan yihiin laakiin way ka baaxad yar yihiin kuwa khibradda u leh miraha SAG.Soo noqnoqoshada korodhay waxa sabab u ah korodhka mugga dallaca (35 – 40% marka loo eego 5 – 10%), xawliyada wax lagu shubo oo sarreeya, iyo tirada badan ee kubbadaha halbeegkiiba.Xoogagga saameynta hoose waxaa ugu wacan isku dhafka labada cufan ee kubbadda yaryar iyo joogitaanka hoose ee hoos u dhaca taasoo ka dhalatay isticmaalka kubbadaha yaryar iyo dhexroorka mishiinka yaryar, siday u kala horreeyaan.

Macdanta quudinta ee miraha shiidida aasaasiga ah ayaa caadi ahaan aad u jajaban taas oo ay ugu wacan tahay cabbirka walxaha, qaabka iyo macdanta.Xiro xawaaraha ku soo socda ama ka badan 20µm/saacaddii.ayaa lagu qiyaasay Au.Cu, iyo Mo ores, halka ay xirtaan xawaarahooda sida 10-15 µm/saacaddii.lagu kulmay macdano hoose oo jilicsan.

Warbahinta shiidida birta ee loo isticmaalo shiidida aasaasiga ah waa in loo qaabeeyey caabbinta xidhashada ugu badan iyadoo la ilaalinayo adkaanta wanaagsan.Adayggu waxa uu si gaar ah muhiim ugu yahay mashiinnada wax lagu shubo ee shabagga, halkaas oo heerarka saxarka ee dhammaadka warshaddu ay u dhowaan karaan eber.

Qiyaasaha Farsamada

| Qaybaha Kiimikada | ||||||||

| Nooca | Qaybaha kiimikada | |||||||

| C | Si | Mn | Cr | Mo | Cu | P | S | |

| Low-Cr | 1.8-3.3 | ≤1.5 | 0.3-1.5 | 1-3 | ≤1.0 | ≤0.8 | ≤0.10 | ≤0.10 |

| Dhexdhexaad-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 4-9 | ≤1.5 | ≤0.8 | ≤0.10 | ≤0.10 |

| Sare-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 10-18 | ≤1.0 | ≤1.2 | ≤0.10 | ≤0.06 |

| Superhigh-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 19-35 | ≤2.0 | ≤1.2 | ≤0.10 | ≤0.06 |

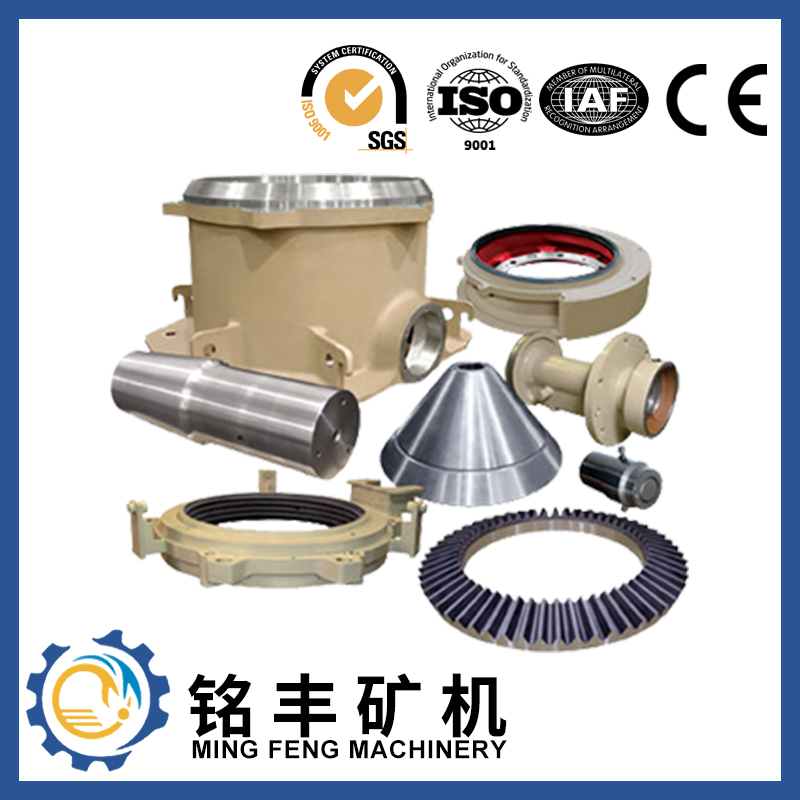

Qaybaha burburiya:

Waxaan haynaa qalab saxan oo lagu beddelo qalabka wax lagu burburiyo oo ay ku jiraan madaxa, maddiibadihii, usheeda dhexe, godka godka, godka, baadiyaha eccentric, bushings madaxa, marsho, countershaft, kaynta countershaft, guryaha countershaft, line dhex weyn ee kursiga iyo in ka badan, waxaan ku taageeri kartaa mashiinkaaga oo dhan qalabka farsamada.

Maxaa noo doora?

Maxaa noo doora?

1.30 sano oo khibrad wax soo saar ah, 6 sano oo khibrad ganacsi shisheeye ah

2. Xakamaynta tayada adag, shaybaadhka gaarka ah

3.ISO9001:2008, BUREAU VERITAS

ALAAB IIBKA KULUL

Tayada Marka hore, Badbaadada waa la damaanad qaaday